Introduction to Custom Mechanical Fabrication Services

With years of experience in air filter manufacturing, DCF (Dong Chau) has established itself as a leading provider of custom mechanical fabrication services in Vietnam. We collaborate with numerous domestic and international businesses to deliver high-quality mechanical products that meet stringent standards, helping clients optimize their product development cycles.

Beyond strong technical capabilities and service, DCF (Dong Chau) continuously fosters long-term partnerships with both local and global partners, aiming to create sustainable value for customers. We proactively update ourselves on new industry trends, embrace innovation in our processes, and implement the most optimal solutions for each project. As a result, our clients always receive products that perfectly match their needs, ensuring smooth operations and business growth in the marketplace.

Common Stainless-Steel Types Used in Custom Fabrication

In custom mechanical fabrication, stainless steel types such as Austenitic, Ferritic, Martensitic, Duplex, and Precipitation-Hardening meet a wide range of modern manufacturing requirements. The most popular grades include 304, 316, 430, 17-4 PH, Duplex, and more. Each type offers specific advantages in durability, workability, formability, hardness, and cost, making them suitable for various applications.

Type | Representative Grades | Durability | Hardness | Workability | Formability | Thermal Conductivity | Cost |

Austenitic | 304, 316, 303, 321, 347 | ★★★★☆ | ★★★☆☆ | ★★★★☆ | ★★★★★ | ★★★☆☆ | ★★★☆☆ |

Ferritic | 430, 409, 434, 439 | ★★★☆☆ | ★★★☆☆ | ★★★☆☆ | ★★★☆☆ | ★★★★☆ | ★★★☆☆ |

Martensitic | 410, 420, 440A, 440C | ★★★★☆ | ★★★★☆ | ★★★☆☆ | ★★☆☆☆ | ★★★☆☆ | ★★★☆☆ |

Duplex | ★★★★★ | ★★★★☆ | ★★★☆☆ | ★★★☆☆ | ★★★☆☆ | ★★★★☆ | |

Precipitation-Hardening | 17-4 PH, 15-5 PH, 13-8 Mo | ★★★★★ | ★★★★★ | ★★★★☆ | ★★★☆☆ | ★★★☆☆ | ★★★★☆ |

If you are interested in a detailed comparison between these steel types, refer to the article “304 vs 316 Stainless Steel and Alloy Steel vs Stainless Steel” to better understand the characteristics and applications of each grade.

Versatile Applications Across Multiple Industries

DCF (Dong Chau) has partnered with clients from diverse sectors, including agriculture, construction, electronics, and industrial equipment. The factory always uses robust materials, modern machinery, and rigorous quality control processes to ensure that every product meets technical requirements and practical application needs.

- Agriculture: Manufacture of durable components and equipment to enhance efficiency and reduce risks during planting and harvesting.

- Construction: Fabrication of heavy-duty parts to increase the lifespan and reliability of construction machinery.

- Electronics & Industry: Supplying high-precision, quality components for electrical devices and industrial machinery, ensuring stable operation.

Boost Efficiency – Reduce Production Costs

Mechanical fabrication at DCF (Dong Chau) helps businesses save production costs by utilizing advanced techniques, optimizing processes, and minimizing material waste. With an extensive supply network, we easily source high-quality materials at competitive prices, contributing to increased profits for customers.

International Standards Compliance

All fabricated products at DCF (Dong Chau) strictly adhere to international standards such as ISO, ASTM, ASME, and more. Our experienced technical team is ready to advise and support customers in meeting the specific requirements of each industry and export market.

Enhanced Performance – Technological Breakthroughs

Beyond simply shaping metal, DCF (Dong Chau) focuses on improving operational efficiency for each product. We support customers throughout the process—from design and material selection to inspection and evaluation of the finished product—ensuring every detail is durable, precise, and long-lasting.

Accelerate Time to Market

DCF (Dong Chau) is equipped with advanced machinery such as CNC cutting machines, stamping machines, and automatic welding systems, which shorten production times and ensure timely delivery. With scientific workflows and a highly skilled engineering team, we guarantee fast, accurate solutions that help customers stay ahead of the competition.

Comprehensive & Diverse Mechanical Fabrication Services

Mechanical fabrication requires the integration of various machines and specialized techniques. At DCF (Dong Chau), we meet all fabrication needs, including:

- Metal casting: Including sand casting, die casting, investment casting—ideal for flexible and cost-effective products.

- Cutting & bending: Using CNC cutting machines and hydraulic presses to achieve clean cuts and precise bends.

- Finishing: Powder coating, galvanizing, anodizing, sandblasting—to enhance aesthetics, durability, and corrosion resistance.

- Metal folding: Shaping complex, multi-dimensional components for demanding structural requirements.

- Hot extrusion: Producing aluminum, steel, and alloy bars to custom cross-sections.

- Laser cutting: Accurate cutting of metal materials with thicknesses ranging from 6mm to 25mm.

- Metal spinning: Fabricating cylindrical, conical, and hollow components as per special designs.

- Metal stamping: High-speed, high-precision mass production of parts.

- Sheet metal fabrication: Integrating cutting, bending, welding, and assembly to produce complete products.

- Water jetting: Effective cutting of thick, heat-sensitive materials without deformation.

- Welding: From TIG and MIG to arc welding, meeting all material and technical requirements.

Innovation – Advancing Fabrication Technology

DCF (Dong Chau) continually adopts the latest technologies such as robotics automation, CNC machining, laser cutting, and water jetting, ensuring products with tight tolerances, complex shapes, and meeting all special customer needs. With ongoing innovation, we provide comprehensive solutions for prototyping, small-batch, and mass production.

Customization – Flexibility for Every Project

Standard products do not always meet practical requirements. DCF (Dong Chau) offers custom mechanical fabrication services, precisely fulfilling all customer specifications. We optimize production processes to ensure fast delivery and consistent quality, from small orders to mass production.

Production Capacity & Customer Service

At DCF (Dong Chau), we manufacture a wide array of products, from electrical components, medical equipment, steel structural parts, advertising products, transportation, to industrial machinery parts. Our experienced engineers work closely with customers—from concept and material selection to prototype design and final product completion.

Contact DCF (Dong Chau) Today

If you are looking for a reliable, professional, and flexible mechanical fabrication partner, choose DCF (Dong Chau) Air Filter Manufacturing Plant. We offer free consultation, instant quotations, and accompany you in turning ideas into reality with exceptional quality, dedicated service, and guaranteed timelines— “our word is our bond.”

Need competitively priced mechanical products without compromising on superior quality? Dong Chau is your ideal choice! We commit to delivering precise, durable, and beautiful mechanical products that meet all technical requirements at the best market price. Contact our hotline at 02862702191 for free consultation and special quotations—Dong Chau is your partner for success: “Quality builds reputation, price drives choice.”

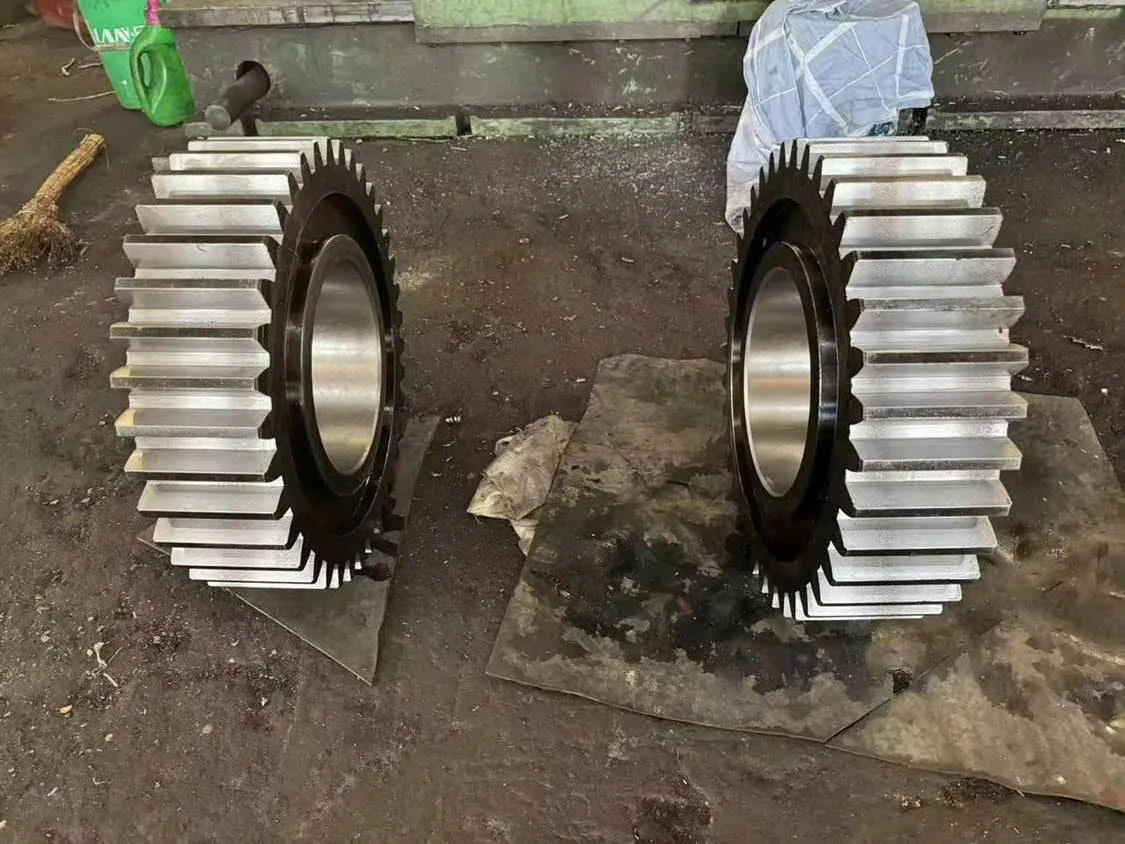

Album hình sản phẩm